0.4mm Transparent Thermoformed PET Sheet in Rolls Supplier

Pulixin is an excellent and leading plastic sheet Manufacturer & factory in China. We have advanced technology and equipment, mature foreign trade and export experience, and have established good cooperative relations with customers in more than 60 countries. Free samples supply, OEM & ODM accepted

- Brand: PULIXIN

- Origin: Shanghai, China

- MOQ: 5 tons

- Thickness: 0.18~1.8mm

- Width: 300~1400mm

- Application: Thermoforming

- Send Inquiry

-

- Email: [email protected]

- Phone: +8615221762039

- WhatApp

- Wechat

Description

As a new material, pet plastic sheet roll has been developed in recent years.

It has excellent toughness, high strength, high transparency, and can be recycled and reused.

The excellent environmental performance of burning does not produce harmful gases, and it is gradually being received by consumers

and The great ambiguity of the people; conform to the trend of environmental protection.

Advantage of PET plastic sheet roll :

1. PET plastic sheet roll has excellent transparency and smoothness, and the display effect is very good.

2. PET plastic sheet roll has Excellent surface decoration performance, can be printed without surface treatment, easy to press pattern, easy metal treatment (vacuum metal plating).

3. PET plastic sheet roll has good mechanical strength.

4. PET plastic sheet roll has good barrier to oxygen and water vapor.

5. PET plastic sheet roll has good chemical resistance, can withstand a variety of chemical substances.

6. Non-toxic, reliable sanitary performance, can be used for packaging of food, medicine and medical equipment, and can be sterilized by Y-rays.

7. PET plastic sheet roll has good adaptability to environmental protection, which can be economically and conveniently recycled; when the waste is incinerated, no harmful substances to the environment are produced.

The thermoforming performance of pet plastic sheet roll is also very good in plastic sheet roll industry, which is equivalent to ordinary PVC sheet.

Vacuum thermoforming can be used to produce PET thermoformed products with excellent performance.

PET platic sheet roll is considered an ideal packaging material that meets environmental protection requirements.

Our Advantages:

|

Product Name |

Professional Pet Plastic Sheet Roll Manufacturer and Supplier in China |

|

Material |

PET vacuum forming material , 100% raw material |

|

Color |

Transparent,black,green or any customized color |

| Thickness Tolerance |

According to GB (higher than GB) |

|

Application |

Vacuum forming packaging, Printing, Bending, Folding box, Cards,etc. |

|

Width |

300~1400mm or Customized |

|

Thickness |

0.15~3mm or Customized |

|

Special Treatment |

Metalized, Anti-UV, Waterproof, Antistatic, Anti-fog, Frosted, Cold resistance, Heat resistance, Double-sided Matte, Conductive. |

|

Features |

1.High temperature resistance, not easily melted |

|

Sample Time |

1-3 days |

|

Delivery Methods |

Ocean shipping ,air transportation, express,land transportation |

|

Payment Term |

Credit card ,T/T,L/C,Western Union,Paypal |

|

Mass Production Lead Time |

3-15 days depend on order quantity |

|

Certificate |

ROHS,MSDS,TDS,SGS,ISO9001 |

|

Core Diameter |

3 inch or 6 inch depend on customer requirement |

|

Packing |

Packing in rolls and plastic pallet,pp woven with PE film and strape on pallet for each roll |

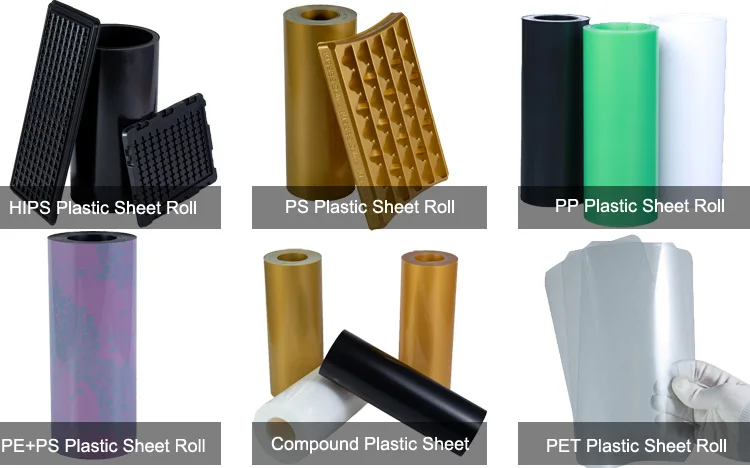

Hot Selling PS / PP / PET Plastic Sheet Roll Products You May Like (Click the Following Pictures)

Our Main Product Categories You May Like (Click the Following Categories)

Company Information

|

Company Profile |

Company Type: Manufacturer |

|

1) Establish Year: 2009 |

|

|

2) Start make export year: 2009 |

|

|

3) Factory area: 5000 square meter |

|

|

4) Patent: Own Many Product Patents |

|

|

5) Total Employees: 50–100 People |

|

|

6) Production Line Capacity: 1000 Metric Tons/Year |

|

|

7) No. of Production Lines: Above 10 |

|

|

8) Certifications: Passed the ISO9001:2008 quality system authentication and ROHS authentication. |

|

|

If you want to find OEM Supplier in China, contact us ! |

Company Video Show

Product parameters

Rigid PET Plastic Sheets – Petg Thermoform Plastic Sheets Bulk

| PET Sheet Roll PROPERTY | UNIT | SA Coated | Print Level | Antiblock Silicon Free | Antistatic Silicon Free | ESD | Conductive |

| THICKNESS OF FILM TESTED | mm | 0.13~ 1.8 | 0.3~0.6 | 0.13~1.8 | 0.25~1.8 | 0.25~1.8 | 0.25~1.8 |

| WIDTH | mm | 350~ 1400 | 350~ 1300 | 600~ 1400 | 600~ 1400 | 600~ 1400 | 600~ 1400 |

| DIAMETER | 300~ 800 | 300~ 800 | 300~ 800 | 300~ 800 | 300~ 800 | 300~ 800 | |

| DENSITY | g/cm3 | 1.35 | 1.35 | 1.35 | 1.35 | 1.35 | 1.35 |

| HAZE | % | 0.7(0.3mm) | 0.7(0.3mm) | 0.8(0.3mm) | 2.0(0.3mm) | 2.0(0.3mm) | 2.0(0.3mm) |

| TOTAL LIGHT TRANSMITTANCE | % | 92(0.3mm) | 91(0.3mm) | 91(0.3mm) | 89(0.3mm) | 89(0.3mm) | 89(0.3mm) |

| TENSILE STRENGTH @YIELD | |||||||

| MD | kg/cm2 | >450 | >450 | >450 | >450 | >450 | >450 |

| TD | kg/cm2 | >450 | >450 | >450 | >450 | >450 | >450 |

| TENSILE MODULUS OF AUTYOUNG | |||||||

| MD | kg/cm2 | >17000 | >17000 | >17000 | >17000 | >17000 | >17000 |

| TD | kg/cm2 | >17000 | >17000 | >17000 | >17000 | >17000 | >17000 |

| ELONGATION @YILED | |||||||

| MD | % | >3.0 | >3.0 | >3.0 | >3.0 | >3.0 | >3.0 |

| TD | % | >3.0 | >3.0 | >3.0 | >3.0 | >3.0 | >3.0 |

| DART IMPACT | |||||||

| LOAD CELL 15KN DIACLAMP | g/mm | >1600 | >1600 | >1600 | >1600 | >1600 | >1600 |

| THERMAL GLASS TRANSITION TEMPERATURE | (℃) | 68 | 68 | 68 | 68 | 68 | 68 |

| CRYSTAL TEMPERATURE | (℃) | 125 | 125 | 125 | 125 | 125 | 125 |

| MELITING TEMPERATURE | 248 | 248 | 248 | 248 | 248 | 248 | 248 |

| RECRYSTAL TEMPERATURE | (℃) | 181 | 181 | 181 | 181 | 181 | 181 |

| ANTI-STATIC RESISTTVTTY RESISTTVTTY, SURFACE(HUMIDITY (50%±2%) (25℃) |

(Ω) | 109-1011 | 106-109 | <106 | |||

| Dyne–SURFACE | 38-40 |

Why Choose Pulixin

PULIXIN is an excellent leading PP plastic sheet roll manufacturer in China. Our factory covers an area of more than 10,000 square meters and has 4 rigid polypropylene sheet production lines with international advanced equipment. It can produce 3,000-5,000 tons of PP plastic sheets per month, and the maximum storage capacity exceeds 10,000 tons.- High Level Factory

- 1, 6000㎡ Area

2, 10 co-extrusion lines

3, 15 years experience

4, 2300+ regular customers

- Considerate Service

- 1, Quick reply to inquiries

2, Free sample on paying the postage

3, Strong capacity, short production and fast delivery

4, Factory inspection acceptable

5, OEM Support

- Strict Quality Control

- 1, Thickness error:+-0.1mm

2, Weight erroe:+-1kg

3, Antistatic impedance: +-0.1Ω

- On Time Delivery

- 1, Production: 1days after prepayment

2, Delivery: 5days after final payment