How to solve the particularly brittle of PP Polypropylene sheet roll and easy to fracture?

Polypropylene (PP) sheets roll need to be used at the right temperature, otherwise the sheets will become light and brittle and easy to break.The operating temperature range of polypropylene (PP) sheet is -30 ~ 140¡æ.

In addition, polypropylene (PP) sheet roll can be blended and modified to make it not easy to fracture.PP (polypropylene) was blended with polyethylene, engineering plastics, thermoplastic elastomer or rubber to improve the performance of PP.

The polymer blend of polypropylene (PP) sheet can synthesize the outstanding performance of each component and make up for the deficiency of the performance of each component.During blending modification, shear force may cause part of macromolecular chains to be cut off to form free radicals and form graft or block copolymers. These new copolymers can also effectively increase the capacity of PP.

The biggest disadvantage of polypropylene is that it is rigid at high temperature and brittle at low temperature.Poor environmental resistance, outdoor use, easy to become yellow and brittle.

The solution to the brittleness of polypropylene is to increase the amount of plasticizer.For example, PP Organic Peroxide Master Batch.

Main usage (M/B — spg-01) :

1. For example, MI12 MI24

Then 25kg/ bag PP + 33g spg-01

MI25 MI50

2. For example, MI12 MI36

Then 25kg/ bag PP + 66g spg-01

MI25 MI75

3. For example, MI12 MI48

Then 25kg/ bag PP + 99g spg-01

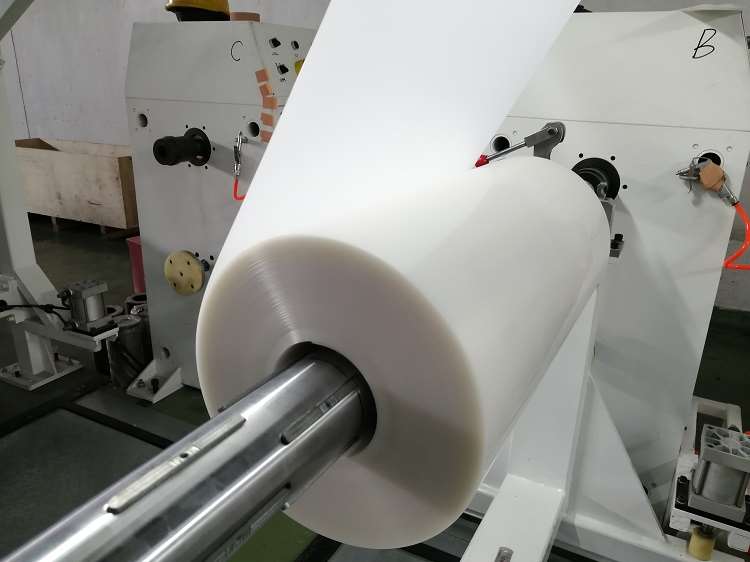

PP sheet roll, not only high transparency, good barrier, low density, non-toxic health, and can be recycled, in the heat or combustion will not produce toxic and harmful gas, do not harm human health, also do not corrode equipment, is a new type of green packaging materials.

PP sheet roll can be made into a variety of products by thermal forming and other secondary processing forms, mainly used for food, medicine, medical equipment and other packaging.Such as processing into jelly box, dairy packaging box, fast food box, cold drink containers, trays, microwave appliances can be used for food packaging;

Blister can be used for the packaging of medicine tablets, capsules and other solid preparations.In foreign countries, especially in developed countries and regions, transparent PP sheet in the field of food packaging applications.

Relative News

- Review of the first day of the 2025 Chinaplas exh…

- Application and unique advantages of light blocki…

- PULIXIN sincerely invites you to visit 2025Chinap…

- Today’s shipment – 20 tons of anti-fr…

- Customer Case: Successful Application of Anti-fre…

- How does the impact resistance of HIPS plastic sh…

- How to choose the appropriate HIPS sheet thicknes…

- Application Cases of PS Plastic Sheets in Thermof…

- Today’s shipment: Antistatic PP plastic she…

- Application Case of Antistatic PP Plastic Sheet &…