Rigid PET Plastic Sheets – Petg Thermoform Plastic Sheets Bulk

Pulixin is an excellent and leading plastic sheet Manufacturer & factory in China. We have advanced technology and equipment, mature foreign trade and export experience, and have established good cooperative relations with customers in more than 60 countries. Free samples supply, OEM & ODM accepted

- Brand: PULIXIN

- Origin: Shanghai, China

- MOQ: 5 tons

- Thickness: 0.18~1.8mm

- Width: 300~1400mm

- Application: Thermoforming

- Send Inquiry

-

- Email: [email protected]

- Phone: +8615221762039

- WhatApp

- Wechat

Description

1. Polyethylene terephthalate (PET), polyethylene terephthalate is commonly known as polyester.

Features of polyester resin:

Polyethylene terephthalate is a crystalline polymer with a density of 1.30~1.38g/cm3 and a melting point of 255°C~260°C. It has the greatest strength and toughness among thermoplastics. Polyethylene terephthalate has a wide range of the temperature range, it maintains its excellent physical and mechanical properties. The temperature of -20°C to 80°C has little effect. The air permeability of polyethylene terephthalate is still good as a packaging material. Low hygroscopicity and maintain dimensional stability.

Polyethylene terephthalate is also resistant to hydrofluoric acid, phosphoric acid, acetic acid, and oxalic acid at higher temperatures, but hydrochloric acid, sulfuric acid, and nitric acid can damage it to varying degrees, such as a decrease in tensile strength. Strong alkali, especially alkali at high temperature, can hydrolyze its surface, and ammonia water has a more dramatic effect. Ethyl acetate, methyl ethyl ketone; xylene, naphtha, methyl ethylene glycol, methanol, acetic acid, etc., are not corroded at room temperature or near their boiling point, and dissolve in o-chlorophenol, tetrachloroethane , Cresol mixed solution or excess nitrobenzene.

Performance of polyester sheet (PET sheet) series:

Polyester sheet series (PET sheet) includes PETG, APET, PCT and other varieties. It is a new sheet product that has been developed and developed rapidly in recent years.

Polyester sheet has many advantages such as excellent comprehensive properties, high transparency, good strength, and easy post-processing. Because of its good strength and the same thickness, its protective effect is obviously better than that of PVC sheet. More importantly, the transparency of polyester sheet increases the packaging effect and makes the packaging a higher grade. In addition, it is non-toxic, odorless, and tasteless, and meets the sanitary requirements of food packaging, and there is no problem of secondary pollution of the environment when PVC sheets are incinerated.

⑴ Amorphous polyester sheet (APET sheet)

APET sheet is obtained by extruding the resin modified by isophthalic acid and diethylene glycol. APET sheet has high transparency; while maintaining many advantages of PET, such as non-toxic, high gloss, good mechanical properties, barrier properties, printing performance; easy to emboss decoration; easy to metallize; can use r-ray Disinfection; waste can be economically treated, including recycling, burning treatment, etc., only carbon dioxide and water are produced during combustion, and no harmful substances are produced. However, APET is not resistant to ultraviolet rays, and APET has good electrical insulation properties.

APET also has many properties that far exceed those of PVC, such as good low temperature resistance and superior friction resistance. It is a promising new plastic packaging material. Its application fields are being further explored and expanded.

The blister molding conditions of APET sheet (Attachment Table 1): molding temperature is 90℃~120℃; mold temperature is 30℃~50℃. After the temperature reaches 120°C, APET becomes turbid and opaque, that is, post-crystallization. For materials with a thickness of 3 to 4 mm, post-crystallization has already started during the heating process. The exhaust channel of APET vacuum forming mold is 20%-30% more than that of HIPS and PVC. APET single film is more difficult to heat seal than composite film. The heat sealing of APET film to APET film (one-component packaging material) is realized in the temperature range of 160~240℃, and the heat sealing time is 0.7~2.5s.

⑵ Amorphous polyester sheet (PETG)

GPET, also known as PETG, is an amorphous PET resin modified with cyclohexanedimethanol. Its melting point is relatively low, only 180°C to 200°C. When PETG sheet has the characteristics of APET sheet, its biggest feature is outstanding heat sealing performance, easy operation during sealing and reliable heat sealing quality. Compared with APET, PETG does not crystallize at a very high molding temperature. For vacuum blister molding, it is even possible to obtain a clear outline of complex geometric shapes, but because of its relatively high price, the application is limited.

The chemical stability of PETG is the same as that of APET. PETG or PETG / APET / PETG full plastic cover can be heat sealed. Bonding is the same as APET. .

⑶ Crystalline Polyester (CPET)

CPET is a PET affected by the crystal nucleus, which can quickly crystallize the material during processing. Heat resistance is a function of the degree of crystallinity formed during thermoforming (the maximum degree of crystallinity can reach 30%). CPET has high barrier properties to air and water vapor. The chemical stability is similar to APET and PETG.

Our Advantages:

|

Product Name |

Rigid PET Plastic Sheets – Petg Thermoform Plastic Sheets Bulk |

|

Material |

PET vacuum forming material , 100% raw material |

|

Color |

Transparent,black,green or any customized color |

| Thickness Tolerance |

According to GB (higher than GB) |

|

Application |

Vacuum forming packaging, Printing, Bending, Folding box, Cards,etc. |

|

Width |

300~1400mm or Customized |

|

Thickness |

0.15~3mm or Customized |

|

Special Treatment |

Metalized, Anti-UV, Waterproof, Antistatic, Anti-fog, Frosted, Cold resistance, Heat resistance, Double-sided Matte, Conductive. |

|

Features |

1.High temperature resistance, not easily melted |

|

Sample Time |

1-3 days |

|

Delivery Methods |

Ocean shipping ,air transportation, express,land transportation |

|

Payment Term |

Credit card ,T/T,L/C,Western Union,Paypal |

|

Mass Production Lead Time |

3-15 days depend on order quantity |

|

Certificate |

ROHS,MSDS,TDS,SGS,ISO9001 |

|

Core Diameter |

3 inch or 6 inch depend on customer requirement |

|

Packing |

Packing in rolls and plastic pallet,pp woven with PE film and strape on pallet for each roll |

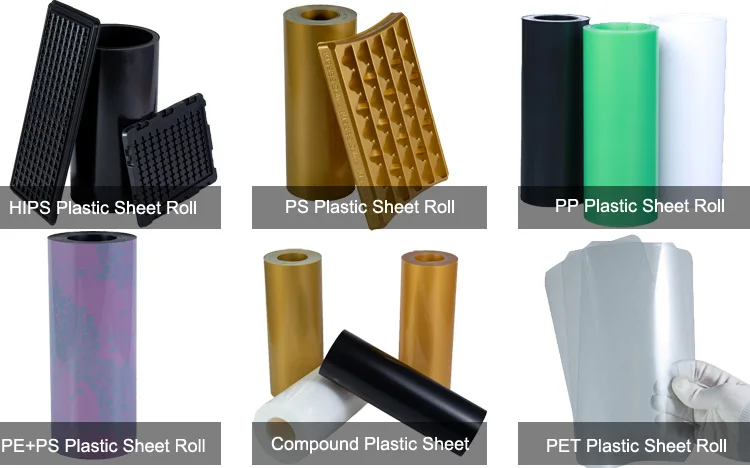

Hot Selling PS / PP / PET Plastic Sheet Roll Products You May Like (Click the Following Pictures)

Our Main Product Categories You May Like (Click the Following Categories)

Company Information

|

Company Profile |

Company Type: Manufacturer |

|

1) Establish Year: 2009 |

|

|

2) Start make export year: 2009 |

|

|

3) Factory area: 5000 square meter |

|

|

4) Patent: Own Many Product Patents |

|

|

5) Total Employees: 50–100 People |

|

|

6) Production Line Capacity: 1000 Metric Tons/Year |

|

|

7) No. of Production Lines: Above 10 |

|

|

8) Certifications: Passed the ISO9001:2008 quality system authentication and ROHS authentication. |

|

|

If you want to find OEM Supplier in China, contact us ! |

Company Video Show

Product parameters

Rigid PET Plastic Sheets – Petg Thermoform Plastic Sheets Bulk

| PET Sheet Roll PROPERTY | UNIT | SA Coated | Print Level | Antiblock Silicon Free | Antistatic Silicon Free | ESD | Conductive |

| THICKNESS OF FILM TESTED | mm | 0.13~ 1.8 | 0.3~0.6 | 0.13~1.8 | 0.25~1.8 | 0.25~1.8 | 0.25~1.8 |

| WIDTH | mm | 350~ 1400 | 350~ 1300 | 600~ 1400 | 600~ 1400 | 600~ 1400 | 600~ 1400 |

| DIAMETER | 300~ 800 | 300~ 800 | 300~ 800 | 300~ 800 | 300~ 800 | 300~ 800 | |

| DENSITY | g/cm3 | 1.35 | 1.35 | 1.35 | 1.35 | 1.35 | 1.35 |

| HAZE | % | 0.7(0.3mm) | 0.7(0.3mm) | 0.8(0.3mm) | 2.0(0.3mm) | 2.0(0.3mm) | 2.0(0.3mm) |

| TOTAL LIGHT TRANSMITTANCE | % | 92(0.3mm) | 91(0.3mm) | 91(0.3mm) | 89(0.3mm) | 89(0.3mm) | 89(0.3mm) |

| TENSILE STRENGTH @YIELD | |||||||

| MD | kg/cm2 | >450 | >450 | >450 | >450 | >450 | >450 |

| TD | kg/cm2 | >450 | >450 | >450 | >450 | >450 | >450 |

| TENSILE MODULUS OF AUTYOUNG | |||||||

| MD | kg/cm2 | >17000 | >17000 | >17000 | >17000 | >17000 | >17000 |

| TD | kg/cm2 | >17000 | >17000 | >17000 | >17000 | >17000 | >17000 |

| ELONGATION @YILED | |||||||

| MD | % | >3.0 | >3.0 | >3.0 | >3.0 | >3.0 | >3.0 |

| TD | % | >3.0 | >3.0 | >3.0 | >3.0 | >3.0 | >3.0 |

| DART IMPACT | |||||||

| LOAD CELL 15KN DIACLAMP | g/mm | >1600 | >1600 | >1600 | >1600 | >1600 | >1600 |

| THERMAL GLASS TRANSITION TEMPERATURE | (℃) | 68 | 68 | 68 | 68 | 68 | 68 |

| CRYSTAL TEMPERATURE | (℃) | 125 | 125 | 125 | 125 | 125 | 125 |

| MELITING TEMPERATURE | 248 | 248 | 248 | 248 | 248 | 248 | 248 |

| RECRYSTAL TEMPERATURE | (℃) | 181 | 181 | 181 | 181 | 181 | 181 |

| ANTI-STATIC RESISTTVTTY RESISTTVTTY, SURFACE(HUMIDITY (50%±2%) (25℃) |

(Ω) | 109-1011 | 106-109 | <106 | |||

| Dyne–SURFACE | 38-40 |

Why Choose Pulixin

PULIXIN is an excellent leading PP plastic sheet roll manufacturer in China. Our factory covers an area of more than 10,000 square meters and has 4 rigid polypropylene sheet production lines with international advanced equipment. It can produce 3,000-5,000 tons of PP plastic sheets per month, and the maximum storage capacity exceeds 10,000 tons.- High Level Factory

- 1, 6000㎡ Area

2, 10 co-extrusion lines

3, 15 years experience

4, 2300+ regular customers

- Considerate Service

- 1, Quick reply to inquiries

2, Free sample on paying the postage

3, Strong capacity, short production and fast delivery

4, Factory inspection acceptable

5, OEM Support

- Strict Quality Control

- 1, Thickness error:+-0.1mm

2, Weight erroe:+-1kg

3, Antistatic impedance: +-0.1Ω

- On Time Delivery

- 1, Production: 1days after prepayment

2, Delivery: 5days after final payment